Extruder with a specially selected 250 kg/hour capacity for producing spiral sleeves for PVC edge bands.

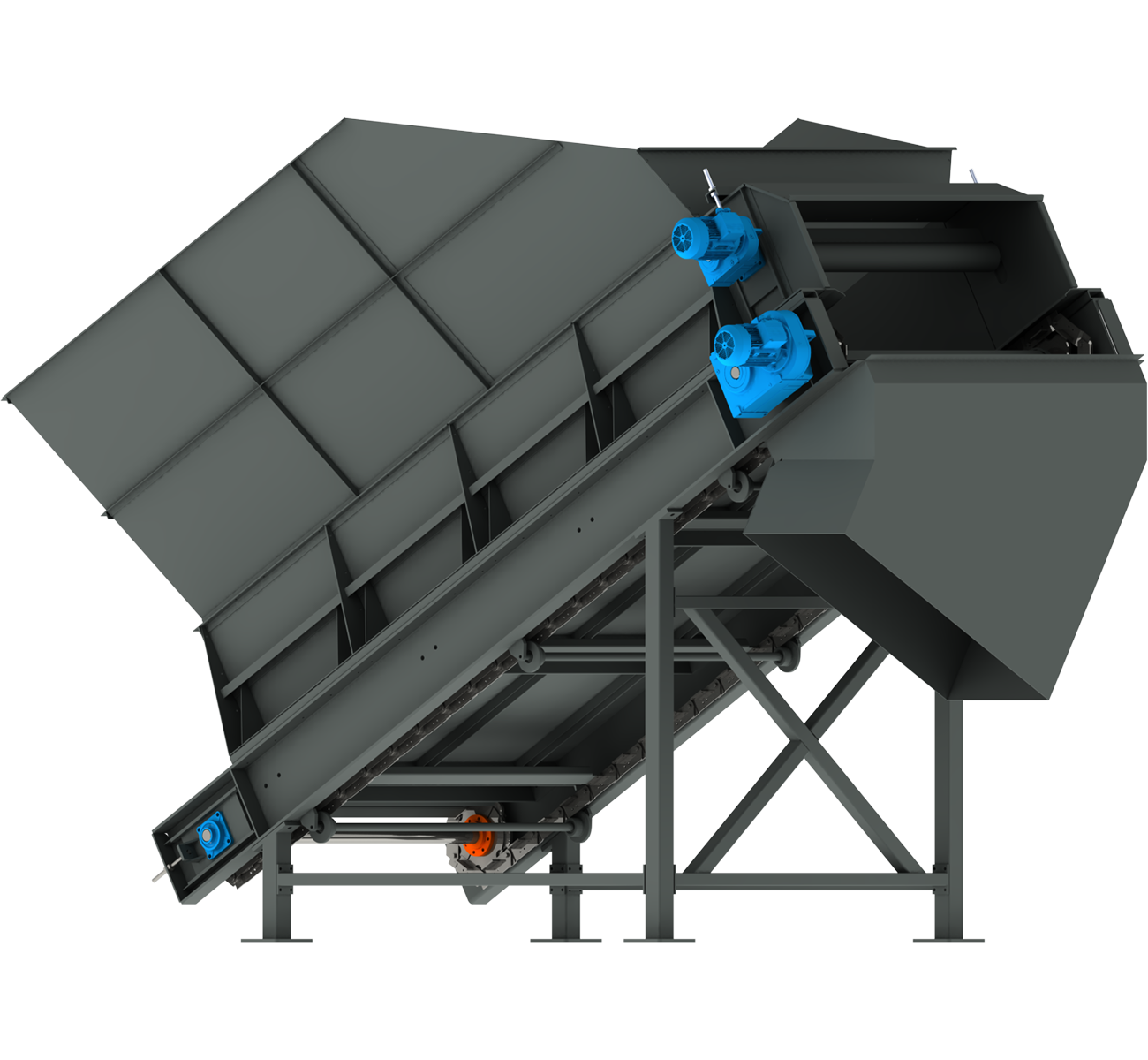

PVC sheet mold that can work with a width of 220 mm and a thickness range of 0.20-2.00 mm.

Possibility to adjust the desired thickness with a flexible head structure and manual adjustment screws.

5-zone cartridge heaters and temperature control.

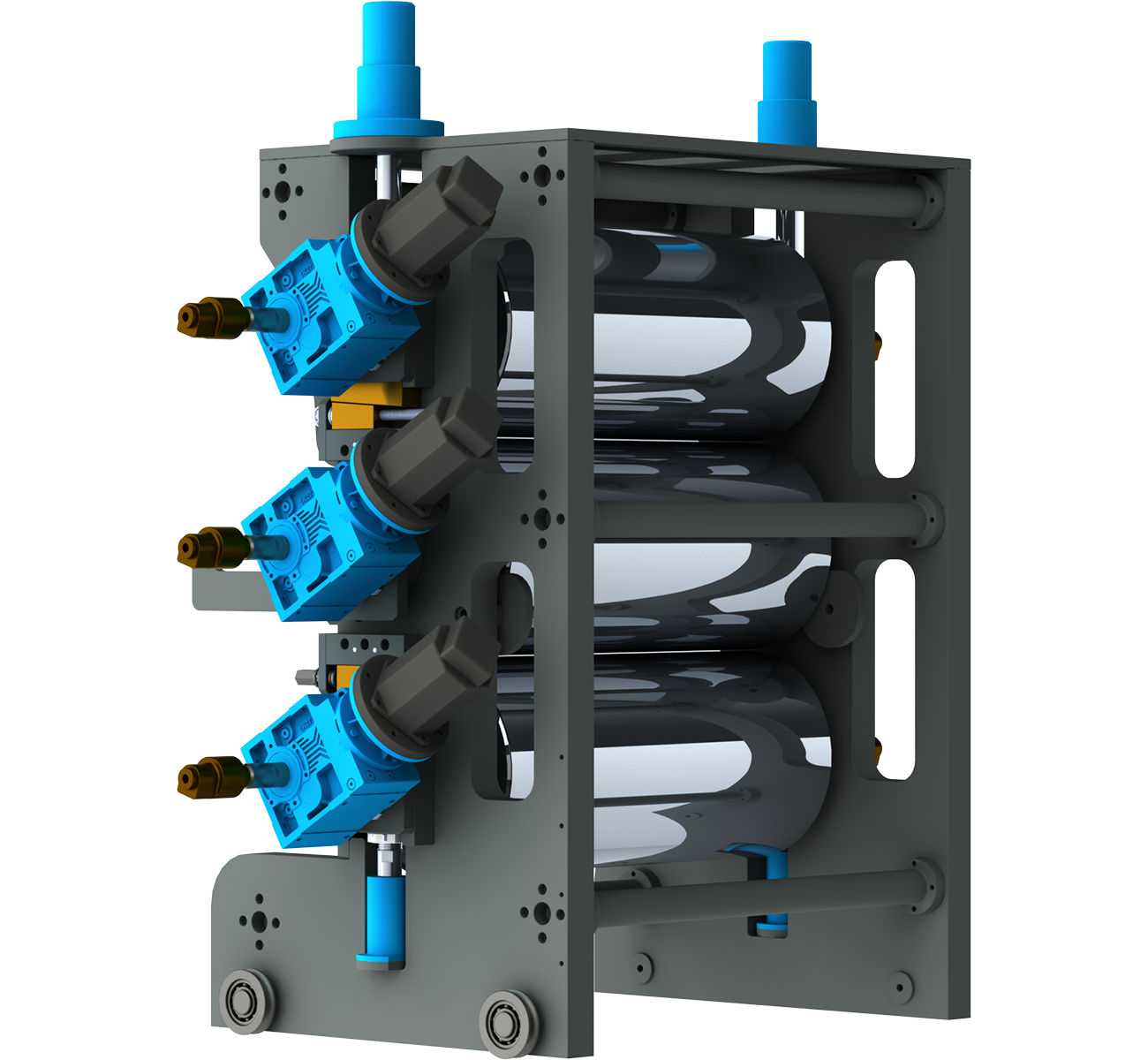

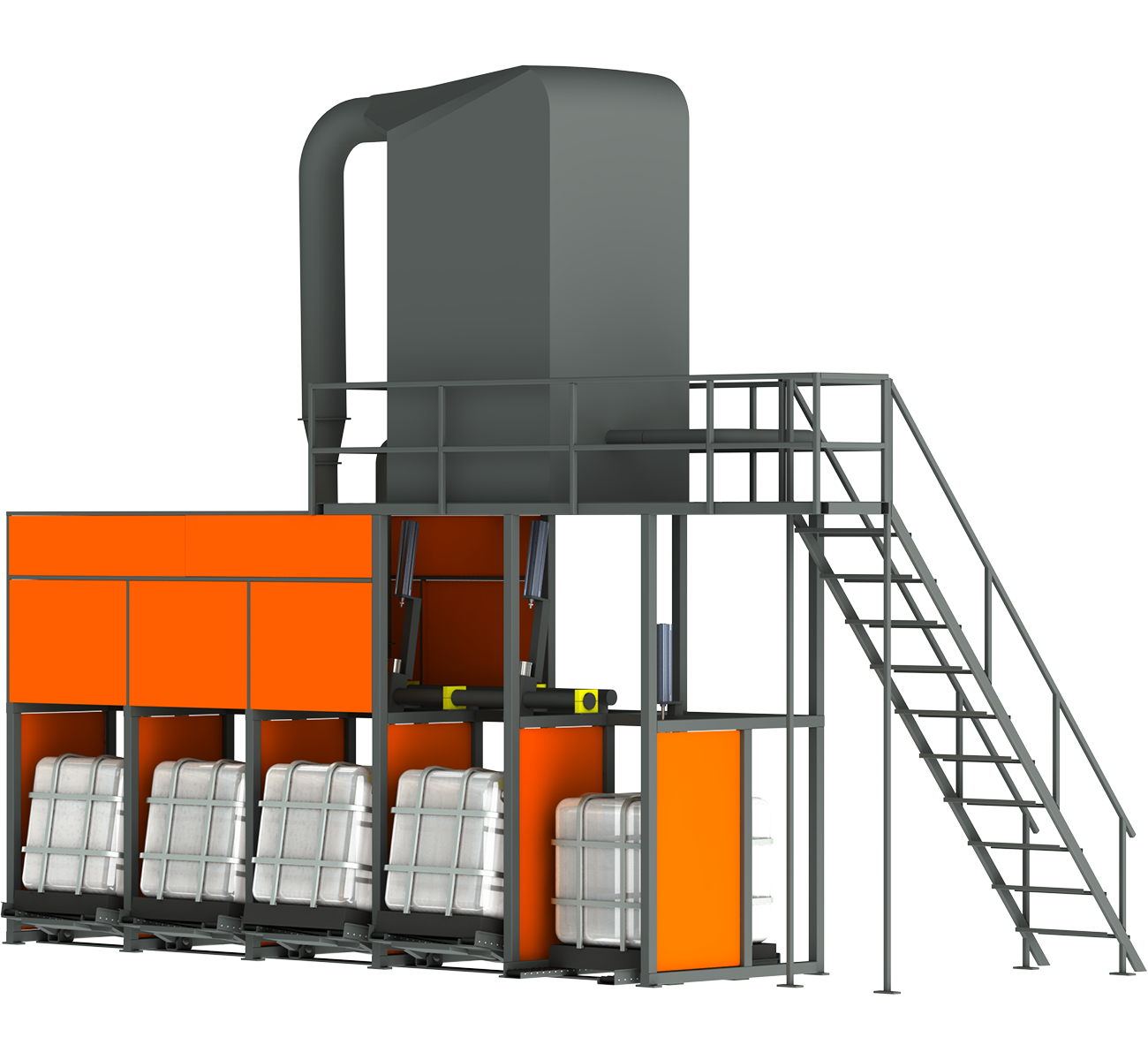

Calendar unit, including 3 water-cooled calendar cylinders. The middle cylinder shapes the surface. Fixtures for changing the middle cylinder for different surface finishes are available on the calendar. The calendar cylinder temperature control is integrated into the thermostatic system. Features an AC motor control system, a precise thickness adjustment system, and a pneumatic system controllable via a touch screen. For maintaining the shape of the PVC sheet and ensuring consistent and standard tension, a water-cooled cylinder system and a pulling unit are provided. The UV coating unit is two-stage to ensure surface durability and protection from external factors. The first stage applies matte UV lacquer, while the second stage applies glossy lacquer. The primer unit increases adhesion strength with adhesive during application. The slitting unit includes 10 sets of upper and lower disc blades, which can be adjusted to the desired gap. The winding unit has 16 torque-adjustable winders, each with meter control.

At the end of the line, the product is finished and ready for shipment in boxes. No additional machinery or systems are required. An adult operator is sufficient to run the line.